Corporate Office

CIN : U51109KA2012PTC04307

For queries: call @ +91 1800 103 7085

Corporate Website: www.karam.in

CIN : U51109KA2012PTC04307

Safety Shoes or Safety boots are footwear designed specifically for moving and working in Industrial, Construction and outdoor environments with your feet fully protected. They are built with a composition of materials that withstand and safeguard against all types of risks that exist in different work settings and go through rigorous multi-layered quality tests that guarantee for their utility. Whether it's the risk of heavy tools falling on feet, exposure to electrical wires, or slippery floors, Safety Shoes with the right soles are crucial in preventing injuries from these workplace dangers.

There are several kinds of industrial workspaces like factories, production assemblies, construction sites, warehouses, oil and chemical extraction and processing plants etc. with activities that make foot protection necessary. Especially, against heavy or sharp objects, slippery surface, hazardous waste, chemical spills etc. These safety shoes bear protective toes, treated fabric/leather texture on its upper surface to provide that sturdiness and layered protection for your feet.

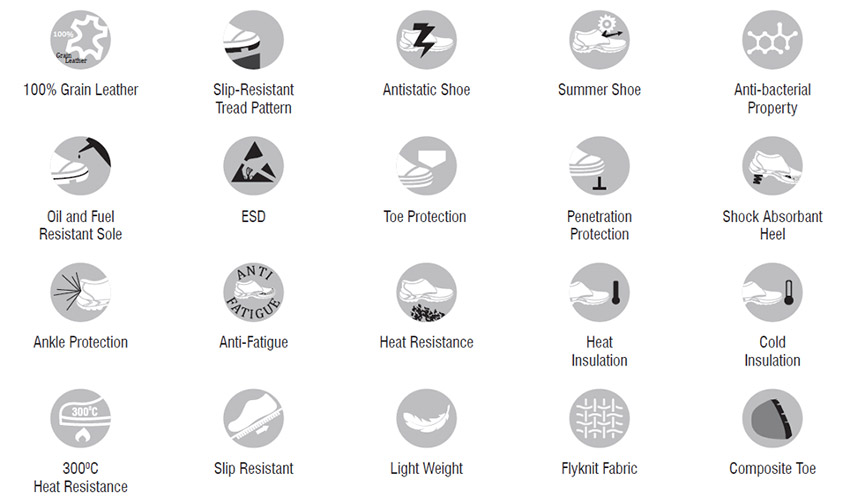

Safety shoes protect against heat, chemicals, oils, shocks, and acids. They come in various options like light weight safety shoes, composite toe safety shoes, and steel toe safety shoes to suit your specific needs. They are also crafted for comfort with features like cushioning and moisture-absorbing lining to keep feet dry and warm. Solid materials in the toe make them strong and long-lasting.

The most critical aspect of using safety shoes is making the right choice in wearing one, based upon certain mandatory conditions that have been thoroughly researched and established for user benefit. Below are some major factors that must be taken into consideration before buying one.

The certification of a safety shoe serves as the strongest point of guarantee and assurance for its quality and compatibility towards the purpose of usage. For a safety shoe to be certified, it adheres to the maximum quality declared under the norm and has appeared in the listed tests and result values mandated under it. Three basic norms for safety shoes in India are:

EN ISO norms (EN ISO 20345) outline requirements for industrial safety shoes, including protection against toe impacts (200 Joules), compression (15 kN) (like 1.5 tones placed on the toe area), slips, oils, and electrical hazards. These standards ensure safety for workers in industries of the European region.

ISI norms (IS 15298:2011) for industrial safety shoes mandate toe impact resistance of 100 Joules, compression resistance of 15 kN, slip and oil resistance, electrical insulation, and durable sole construction. This standard ensures safety and protection for workers in various industrial environments.

DGMS (Directorate General of Mines Safety) certification ensures industrial safety shoes meet standards for use in Indian mining environments, guaranteeing protection against hazards like falling objects and electrical risks. Manufacturers adhere to DGMS requirements, subjecting their products to rigorous testing to attain certification, marking them as safe and reliable for miners.

For a safety shoe to be effective it requires a comprehensive built, with a few above listed properties. These compositions vary based upon the scenario for which the shoes are required. Hence, they are classified into different protection categories as listed below.

S1:Has all the characteristics present with SB along with some additional properties like;

S2:Has all the characteristics present with S1 along with additional properties like.

S3:Has all the characteristics present with S2 along with additional properties like.

There are various activities across diverse industries such as mining, construction, manufacturing, chemical production, heat furnaces, Information technology etc. Due to the risks involved with the equipment and materials that take a central part in the working of these industries, choosing the right safety shoe based upon the subject scenario becomes critical. For instance, Antistatic safety shoes are essential in sectors like petrochemicals, flammable chemicals, pharmaceuticals, paints and adhesives, automobile, and IT industry. ESD safety shoes are compulsory in fields involving computers, electronics and circuits, and ordnance arms and ammunitions.

Based upon the area/situation/scenario of usage, safety shoes can be selected keeping the following factors in mind.

Sole Type: The below listed soles play a vital role in ensuring safety with other required attributes.

Toe Caps: They have a central role in adherence to upper safety requirements for safety shoes and are mainly of two types:

Leather/Fabric: The upper of the safety shoes are the first line of defense against industrial hazards. Primarily safety shoes deploy two kinds of upper based on:

Internal/Outdoor Environments:Industrial functions require an overall 360˚ coverage over different working scenarios and risks; thus, making them a prime factor for selection of safety shoes. For simplification, it can be mainly bifurcated into two.

Login/Sign up with your mobile number to get started

Enter the OTP code sent to your mobile number to complete the verification process.